Quality Policy

Quality Assurance

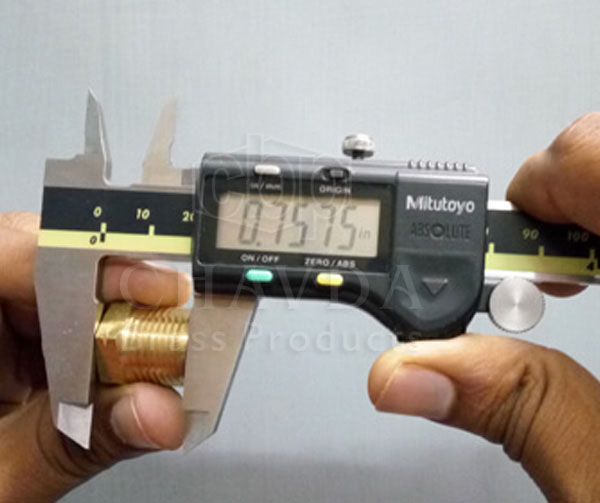

Each component produced at Chavda Brass Products follows stringent quality procedures and vigorous quality checking at all stages of manufacturing cycle to ensure that near zero defect components are supplied to our valued customers.

To support our near zero defect component manufacturing philosophy, we train all our staff on regular basis to keep them up to date regarding latest instruments and latest trend in quality.

We keep on updating and upgrading our instruments as per customer and component requirements, so as to assure supply of best quality products to our customers.

Quality Testing Equipments

Profile Projector

Spectro Machine

Hardness Tester Machine

Digital Vernier Calliper

Digital Micro Meter

Threaded Plug Gauges

Quality Control

We have quality control department, which ensures that each product manufactured as exactly to the drawing and each process are controlled and the quality of the parts maintained throughout the entire process.

We follow rigorous controls like Material control, Process control, Machining and Dimensional control, Assembly line quality control, Leakage / Pressure testing along with supplementary tests to ensure that our range is free from all kinds of defects. Due to our ethical business policies, we have been able to serve our esteemed clients, located across the globe. We provide inspection reports, raw material test report to our customers.